Olympus

DePuy Synthes

Ethicon

California Polytechnic State University

Biosense Webster

Amway

Bio-Rad Laboratories

Johnson & Johnson

Why Record Video?

Lean transformations rely heavily on process observation

- Therefore they require a deep understanding of the details

- “Time and motion type” studies are critical elements

- Traditional methods use video cameras & spreadsheets

As a Result

They are extremely time consuming

leanEdit is 60%

Faster than traditional methods

Traditional Approach to Video Tape Analysis

Video the process or the operator

Playback video on a TV or computer

Manually enter the time for each step while playing back video

Issues With Traditional Video Analysis

- The engineer must keep track of separate video & analysis files

- Locating video clip end-points for replay is difficult & time consuming

- Continuous toggling between videos & spreadsheets

- Storage/retrieval of media is cumbersome

- Limited ability for collaborative analysis and sharing of best practices

- Manual entry & calculations using spreadsheets is time consuming and leads to errors

The leanEdit Process

Video the process or the operator using a smart device and then upload the video into leanEdit.

Individual Users

Upload video to your leanEdit.com account

Small Teams

Use our laptop version to analyze using your PC

Enterprise Customers

Upload video to leanEdit deployed on your own server

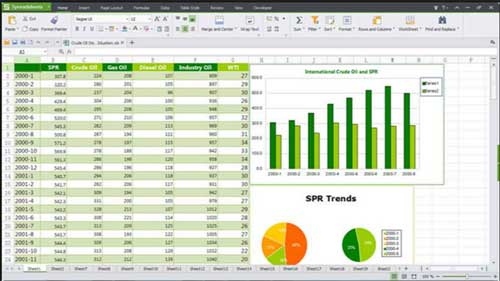

Capture and Categorize

leanEdit captures and categorizes work content through the creation of separate video clips that can be played back on demand

leanEdit’s user friendly interface catalogues your videos and projects as well as providing a facility to capture favorite video clips. It’s fully editable and generates detailed reports within the application itself that can also be exported as a spreadsheet.

leanEdit utilizes the benefits of mobile devices to shoot video and combines it with a powerful, integrated application that breaks your process into clips for deep process analysis.

Simple, easy to use interface!

Customize your categories

Identify and merge “Favorite” clips for review

Up to 60% faster than traditional video analysis methods!

Merge multiple videos

Full search capability

Export your results for easy manipulation of data!

“Current” and “Future” view options to simplify data review

Download clips or projects at any time for use in other applications

Real Time Analysis

Steps can be eliminated or future state times identified for each clip

Accelerate your continuous improvement efforts through the use of four different analysis tools including “Labor Analysis,” “Multi Cycle Analysis,” “Set Up Reduction,” and “Process Flow Analysis.”

Share projects with colleagues using our web-based versions or manage projects on your PC with our desktop format.

Additional Advantages

Standard work created in leanEdit can be used to train new employees!

Introduces video analysis as a practical solution for a wider range of processes

Web versions leverage connectivity to search, identify and share Best Practices across the Enterprise

Laptop version is portable and convenient for instant analysis, anywhere!

As Referenced In Published Media

Don’t just take our word for it. See what industry professionals have to say about the use of leanEdit in your business.

The BASICS Lean Implementation Model

In 2004 Charlie Protzman created The BASICS Lean Implementation Model, which covers the full spectrum of what is needed to be effective and successful at implementing a ... Click to read more on Amazon

Lean Analysis Done Lean

“Our site has recently used the LeanEdit software to analyze cleaning choreography and setup activities for individual work-centers in manufacturing as well as our packaging lines. The software has reduced our analysis time by greater than 60% and is yielding better analysis.

In addition, to these traditional uses, we have recently identified that there is a training application that we will be trialing. We are in the process of executing Factory Acceptance Tests for a new packaging line. During the Factory Acceptance Tests our Process Engineers will be filming the change-over at the vendor, editing the video to show only the ideal execution and then using the output as a training video for operators so they are familiar with the equipment and change-over activities. We hope this will reduce our go –live ramp up.”

Operations Business Unit Manager

Bring your continuous improvement projects into the 21st century with leanEdit – lean analysis done lean!

Contact Us

Just starting to look into lean analysis? Interested in improving your current process? We can help!